Gas pipe network inspection according to G 465-1

Schütz GmbH Messtechnik is a certified company for gas pipe network inspection by the German Administration of Gas and Water (DVGW). We have been working closely with our customers for many years. We work throughout Germany, our gas detectors are also quickly on site at your location. We would be happy to send you our reference list.

Schütz GmbH Messtechnik is a certified company for gas pipe network inspection by the German Administration of Gas and Water (DVGW). We have been working closely with our customers for many years. We work throughout Germany, our gas detectors are also quickly on site at your location. We would be happy to send you our reference list.

Continuous testing verifies extensive knowledge of gas detection work, the existence of the relevant rules and regulations and other regulations and checks them externally. Gas pipe network operators who check their pipeline system in-house are very welcome to obtain the necessary hardware and software from us.

Benefit from our many years of experience in gas pipe network control. Schütz Messtechnik, as a reliable partner in pipe network inspection, offers you recognized and leading state-of-the-art hardware and software technology as well as the security of a service provider certified by DVGW according to ISO 9000.

Complete systems from Schütz Messtechnik

- Tried and tested hardware that is qualified in practice

- Set up and test the system

- Complete test including detection device

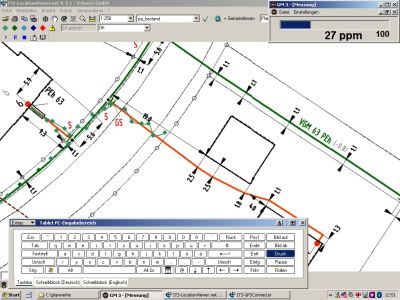

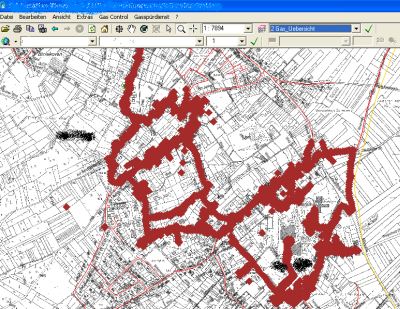

Energy suppliers who use a geographic information system (GIS) can have their network checked using digital technology from Schütz.

Use of digital plans

The management of all pipe network information with a geographic information system (GIS) is already standard for modern energy supply companies. However, the regular gas pipe network inspection is often still carried out in the conventional manner with plans on paper. Printing out and assembling the plans, handling the plans by the gas detector during the control and manual entry of the data obtained during the review are work steps that - time-consuming and expensive - still have to be carried out with the previous working method.

The management of all pipe network information with a geographic information system (GIS) is already standard for modern energy supply companies. However, the regular gas pipe network inspection is often still carried out in the conventional manner with plans on paper. Printing out and assembling the plans, handling the plans by the gas detector during the control and manual entry of the data obtained during the review are work steps that - time-consuming and expensive - still have to be carried out with the previous working method.

If you want to take full advantage of your GIS, Schütz Messetechnik now offers you a modern, inexpensive and at the same time safe alternative for gas pipe network inspection. Equipped with an electronic field information system, the gas detectors from Schütz are able to have the entire plan digitally available on site. The network operator only needs to provide the relevant plan sections on a USB stick.

The gas detector can read the data into a field-compatible computer and use it directly when inspecting the line. With the help of a GPS receiver (= Global Positioning System) the gas detector can determine his position and automatically follow the plan. An electronic damage sketch in accordance with DVGW can be created and completed for documentation of any damage that appears during the inspection.

Advantages of an electronically supported gas pipe network inspection

-

You take full advantage of the possibilities of your GIS

-

You reduce your effort considerably

-

You increase efficiency and security through digital documentation

-

You create better predictability and advantages for your work preparation

-

You significantly increase the quality of the documentation

Checklist for Data Exchange

- Send sample data for review before the start of the job

- Determine the visibility as required for the pipeline network inspection

- Make sure the dimensions are easy to read (height approx.1.3m)

- Highlight the gas pipe clearly, if possible red

- For graphic data, reduce the number of colors to 16

- For dxf data, use an older format (e.g. dxf 14)

- For dwg data, use an older format (e.g. dwg 14)

- The dxf or dwg file size should not exceed 50 to 80MB

- Send data to us at least 2 weeks before the start of work

DXF DWG Data Exchange

With vector data formats (dxf, dwg ..) problems and processing time and again arise due to many special adaptations and interfaces used. As an example, the use of blocks in dwg (ACAD) format, these blocks have to be resolved during export, otherwise the visualization is no longer saved.

The Following Issues are Often a Cause for Manual Post-Processing

- Special characters coding, for example umlauts are no longer displayed

- Blocks are not resolved

- The thickness of the line is too narrow and cannot be seen on the portable device

- The color of the cable is not suitable and cannot be recognized on the portable device

- The files are too large and can no longer be loaded

- Dimensions too small are no longer legible

Only in exceptional cases can dxf dwg or other vector data be used without post-processing. Alternatively, the data can already be tiled, but processing is then no longer possible, so the necessary specifications for using the plan on a tablet PC for the above-ground inspection of the gas pipe network must be met.

Recommended Test Cycles

According G465-1 05/2019 Pressure Rating up to 16 bar, Underground Pipelines,

Review periods in developed areas

| Leakpoint Frequency per km | ≤ 0,1 | ≤ 0,5 | ≤ 1 |

|---|---|---|---|

| =1 bar | 6* | 4 | 2 |

| ≤ 5 bar | 4* | 2 | 1 |

| > 5 up to ≤ 16 bar | 1 | ||

| Cycles in Years | |||

* Diese Überprüfungszeiträume gelten nur für PE-Leitungen und kathodisch geschützte Stahlleitungen.

The inspection cycle must be changed according to the leaks found during the previous inspection. For example, if 9 leak points were found during the last pipe network inspection and a total network of 10 km (leakage frequency: 9/10 = 0.9) was checked in a 24 mbar network, a pipe network check must be carried out again on this network in two years.

According G465-1 05/2019 Pressure rating up to 16 bar, underground pipelines,

Review periods outside of developed areas

| Leakpoint Frequency per km | ≤ 0,1 | ≤ 0,5 | ≤ 1 |

|---|---|---|---|

| ≤ 5 bar | 6 | 6 | ;2 |

| > 5 up to ≤ 16 bar | 2 | ||

| Cycles in Years | |||

The above-ground leak survey can be replaced only when a walk-by or drive-by inspection is completed at least every four months or a fly-by inspection is completed monthly and a walk-by inspection is completed biannually.

The frequency of fly-bys can be extended to two months if the operational experience, the results of the reporting and the local conditions allow it. This only applies to PE lines and cathodically protected steel

According to G466-1 pressure rating over 16 bar, underground pipe

The pipeline is closer than 20m to buildings

- Drive-by or walk-by inspection every 2 months

- Extract once a year

According G614, gas pipelines on factory premises

Review Period 1 year after completion, minimally every 6 years Thereafter, see G614-2

- Tightness of the detachable, non-detachable connections

- Condition of the fastenings, corrosion protection, color coding

- Functionality and accessibility of fittings and other pipeline parts

- nspection of the wall and ceiling duct

- Inspection of the gas-tight storage of pipe end closures

- Inspection of the documentation for completeness

Inspection Period according TRGI DVGW G 600 (less than 1 bar)

- Annual visual inspection, pay particular attention to the smell of gas

- Usability check every 12 years